| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : PFT

Model Number : OEM

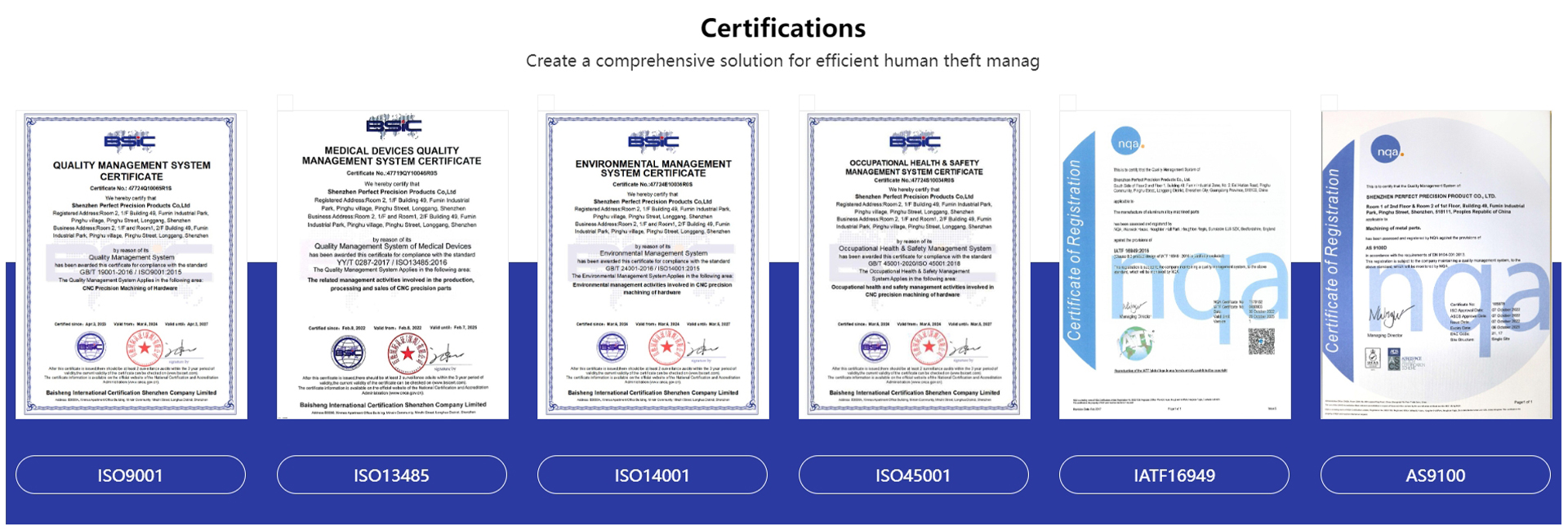

Certification : ISO9001:2015, ISO13485:2016

Place of Origin : Guangdong, China

MOQ : 1PC

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10000Pcs/ Month

Delivery Time : 7-15 work days

Packaging Details : As the requirement of custome

Cnc machining or not : CNC Machining

Micro machining or not : Micro Machining

Service : OEM/ODM

Application : mechanical parts etc,Household

Product name : Professional Precision Cnc Machining Parts

Lead time : 7days

In today's highly competitive market environment, custom plastic parts precision shell processing has become an indispensable part of many industries. Whether it is electronic equipment, automotive parts or medical devices, the manufacture of precision shells requires extremely high precision and stability. As a factory focusing on this field, we always adhere to customer-centricity and quality-centricity, and are committed to providing customers with high-quality, high-precision customized solutions.

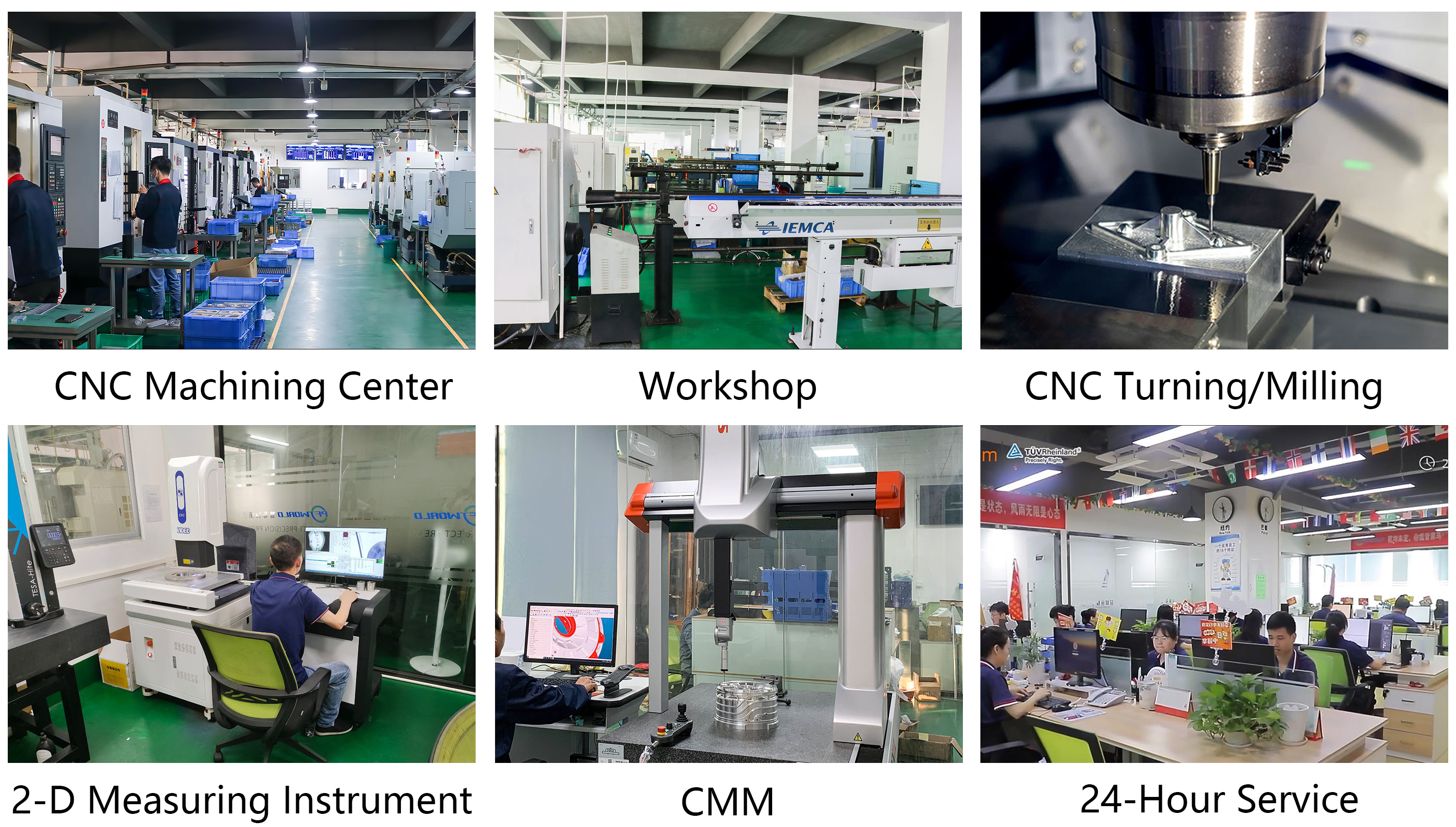

Advanced production equipment to ensure efficient production

We are well aware that advanced production equipment is an important guarantee for achieving high-quality products. To this end, we have introduced a number of high-precision CNC machine tools and laser cutting equipment to ensure that every processing detail can achieve millimeter-level accuracy. These equipment not only improves production efficiency, but also greatly reduces manual errors, making our products more competitive in the market.

Exquisite production technology to create excellent quality

In the production process, we always adhere to the concept of "keep improving". From the selection of raw materials to the inspection of finished products, every link is strictly controlled. We use internationally advanced processing technology, such as injection molding, CNC processing and surface treatment, to ensure that the products can meet the high standards of customers in appearance, structure and function.

Strict quality control system to ensure reliable products

Quality is the lifeline of enterprise survival and development. We have established a complete quality management system, covering the whole process from raw material inspection, production process monitoring to finished product testing. Each batch of products will go through multiple quality inspection processes before leaving the factory to ensure that it meets international standards and customers' specific requirements. In addition, we also provide third-party test reports to enhance customers' trust.

Rich and diverse product categories to meet diverse needs

We not only focus on the processing of precision housings, but also provide customized services for a variety of plastic parts, including housings, brackets, connectors, seals, etc. Whether customers need standard parts or customized parts with special specifications, we can provide flexible solutions according to their needs. Our products are widely used in electronics, automobiles, medical, industrial equipment and other fields, and are well received by customers.

Perfect after-sales service to enhance customer experience

We are well aware that good after-sales service is an important guarantee for long-term cooperation with customers. We provide 7×24 hours of technical support and quick response services to ensure that any problems encountered by customers during use can be solved in time. In addition, we also provide product maintenance, upgrade suggestions and regular return visits to help customers use our products better.

1. Are you a manufacturer or a trading company?

|

|

Customized plastic parts precision shell processing Images |