| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : PFT

Model Number : OEM

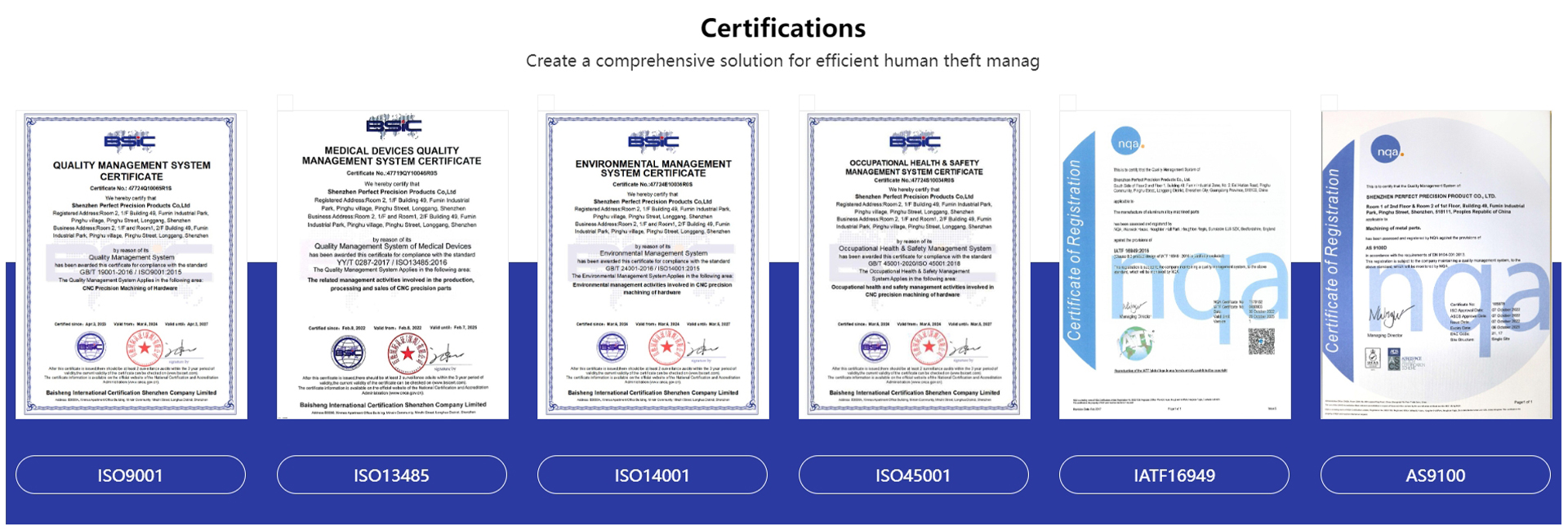

Certification : ISO9001:2015, ISO13485:2016

Place of Origin : Guangdong, China

MOQ : 1PC

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10000Pcs/ Month

Delivery Time : 7-15 work days

Packaging Details : As the requirement of custome

Cnc machining or not : CNC Machining

Micro machining or not : Micro Machining

Type : Turning,Milling,Other Machining Services

Material capabilities : Aluminum,Stainless Steel,Hardened Metals,Plastic

Material : Aluminum,Stainless Steel,Copper,Brass.Plastic

Surface treatment : Sandblasting,Anodizing,Plating,Laser Engraving,Polishing,Bushing,Powder Coating

Process : CNC Turning,CNC Milling,CNC Turn-mill Compound

Tolerance : + - 0.01 mm,0.002~0.01mm

Application : Auto,Electrical,Industrial machine equipment

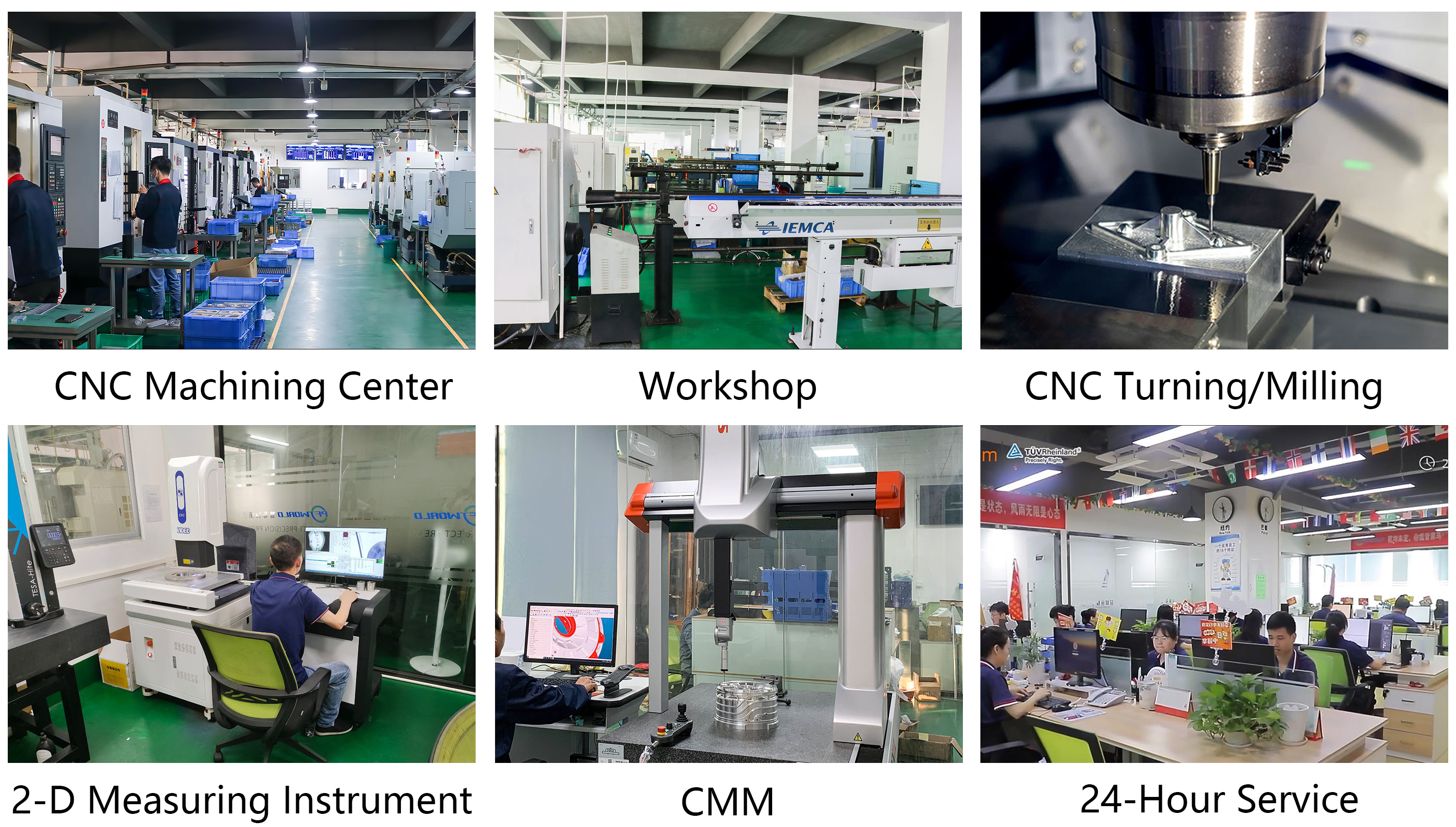

In today’s fast-paced manufacturing industry, high-quality and reliable components are critical to the success of any product. Among the most sought-after solutions are OEM CNC machining aluminum parts, known for their durability, lightweight properties, and exceptional performance in various applications. Whether for aerospace, automotive, electronics, or medical devices, the demand for precision-engineered aluminum components continues to grow. This article explores the complete process, from CNC turning to anodizing services, and highlights why OEMs rely on specialized manufacturers for their aluminum machining needs.

Understanding CNC Machining for OEM Aluminum Parts

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed software controls the movement of machinery and tools. For aluminum parts, CNC machining provides a high level of accuracy, repeatability, and speed, making it ideal for OEM (Original Equipment Manufacturer) applications.

Aluminum is particularly favored due to its:

These properties make aluminum parts suitable for complex geometries and critical tolerances often required by OEMs in industries such as robotics, aviation, and electronics.

CNC Turning: Precision in Every Rotation

A key aspect of aluminum machining is CNC turning, a process where a cutting tool removes material from a rotating workpiece to create cylindrical parts. Turning is ideal for components like shafts, pins, bushings, and housings.

Advantages of CNC turning for aluminum parts include:

OEM clients benefit from consistent output and minimal material waste, contributing to both cost efficiency and product reliability.

Anodizing Services: Enhancing Surface Performance

After machining and turning, anodizing is a crucial finishing process for aluminum parts. Anodizing is an electrochemical treatment that forms a protective oxide layer on the aluminum surface, improving both aesthetics and functionality.

Key benefits of anodizing services include:

This process not only protects the aluminum part but also adds a sleek, professional appearance — a critical aspect for many OEMs seeking premium-looking components.

1. Are you a manufacturer or a trading company?

|

|

OEM CNC Machining Aluminum Parts Turning Anodizing Services Images |