Anodized Surface Stamping Parts

Anodized surface stamping parts combine metal stamping with an electrochemical finishing process to create durable, high-quality components for industrial applications.

Process Overview

- Stamping: High-precision forming of metal sheets using custom dies for mass production

- Anodizing: Electrochemical process that enhances aluminum's natural oxide layer for superior surface properties

Key Advantages

- Enhanced Durability: Hard anodized surface resists scratches, wear, and corrosion

- Permanent Coloring: Dyes penetrate the oxide layer for fade-resistant colors

- Material Integrity: Anodic layer grows from base metal, preventing peeling or flaking

- Electrical Insulation: Ideal for electronic components and housings

Common Applications

- Electronics faceplates and bezels

- Automotive trim and components

- Aerospace interior parts

- High-end consumer goods

Technical Specifications

| Processing | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, EDM, Injection Molding, 3D Printing, Rapid Prototype, Moulds |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052

Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH

Steel: 1214L/1215/1045/4140/SCM440/40CrMo

Brass: 260, C360, H59-H70, Bronze, Copper

Titanium: Grade F1-F5

Plastic: POM, PA, PC, PMMA, PVC, PU, Acrylic, ABS, PTFE, PEEK |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Various Metal Platings, Brushing, Painting, Powder Coating, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engraving |

| Tolerance | ±0.002 ~ ±0.005mm |

| Surface Roughness | Min Ra 0.1~3.2 |

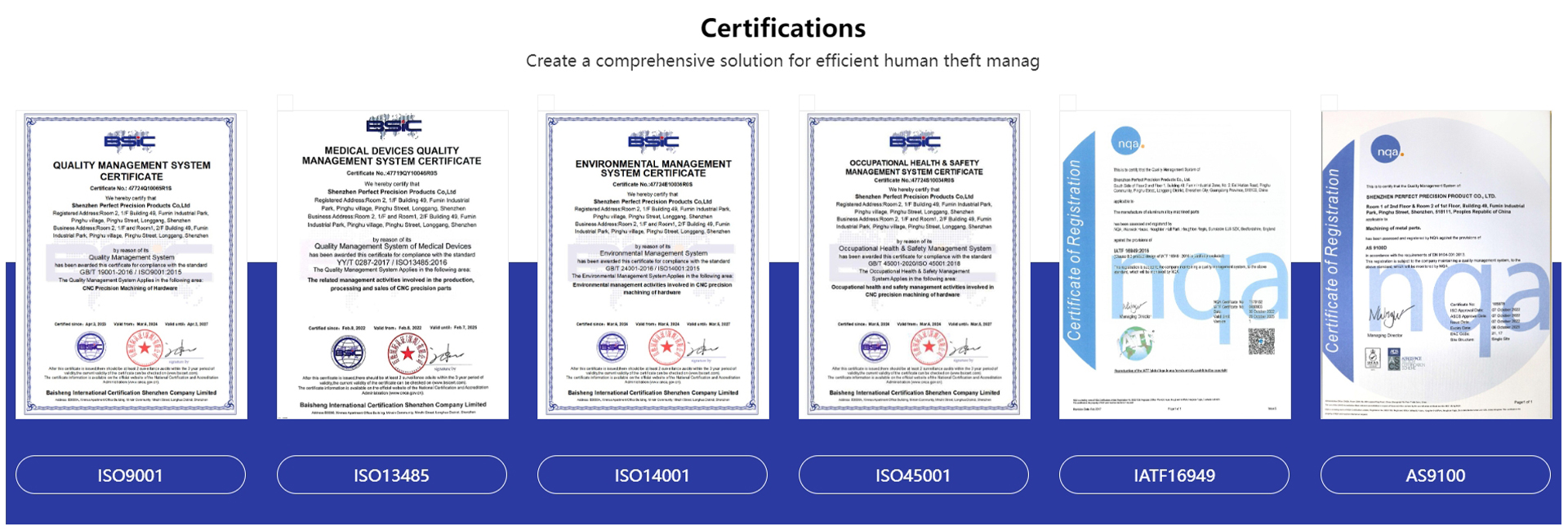

| Certifications | ISO9001:2015, AS9100D, ISO13485:2016, ISO45001:2018, IATF16949:2016, ISO14001:2015, ROSH, CE |

Frequently Asked Questions

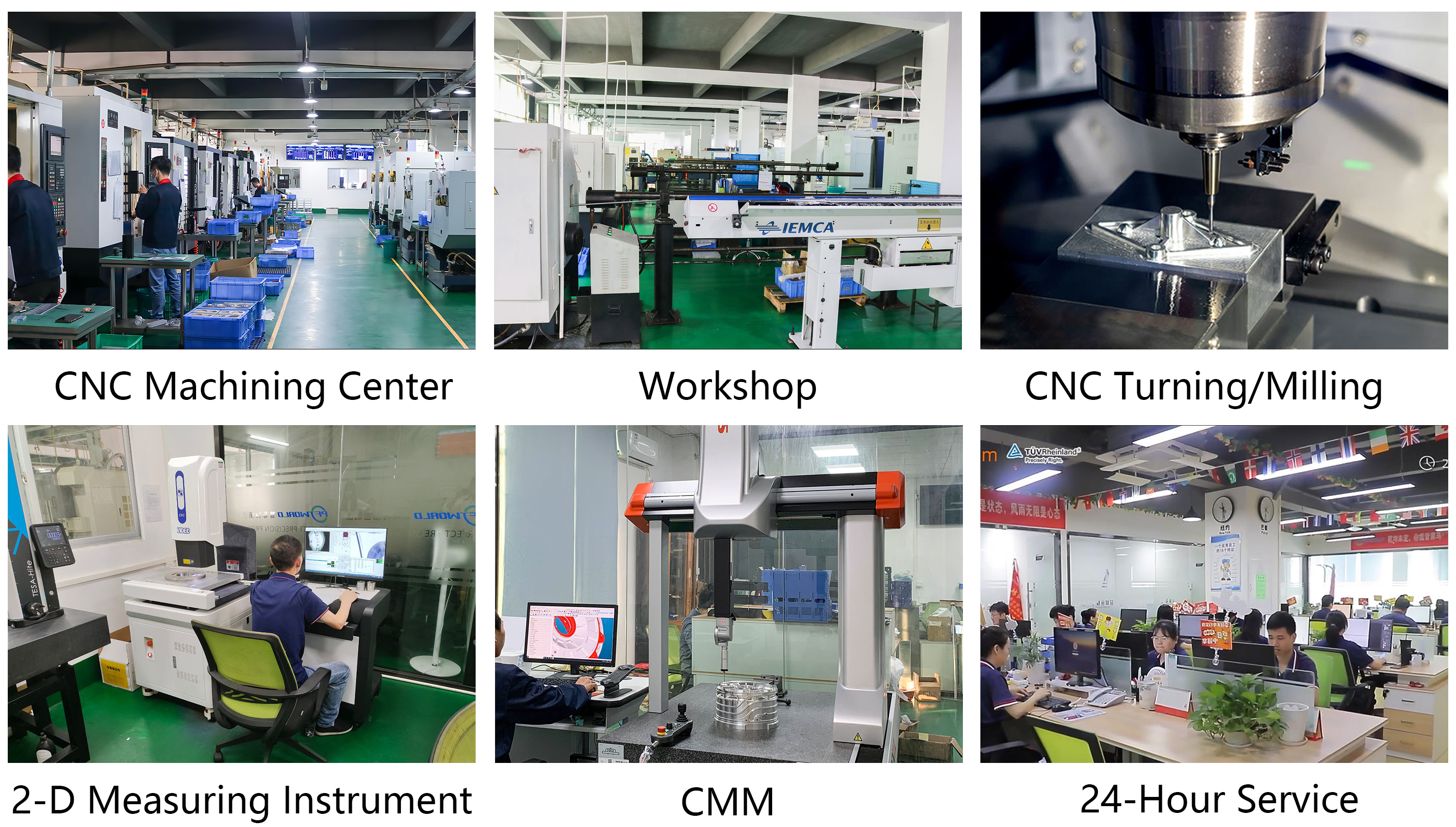

Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of experience covering 6000 square meters. Our facilities include 3D quality inspection equipment, ERP system and 40 machines. We can provide material certificates and quality inspection reports.

How to get a quote?

Please provide detailed drawings (PDF/STEP/IGS/DWG) including quality requirements, delivery date, materials, quantity, and surface treatment specifications.

Can I get a quotation without drawings?

We can work from samples, pictures, or detailed size drafts to provide accurate quotations. Our engineering team can also assist with design.

Can you provide samples before mass production?

Yes, sample production is available with fees typically credited against future mass production orders.

What is the delivery date?

Samples typically require 1-2 weeks, while batch production takes 3-4 weeks.

How do you control quality?

- Material Inspection - Check surfaces and approximate dimensions

- First production inspection - Verify critical dimensions

- Sampling inspection - Quality check before warehousing

- Preshipment inspection - 100% inspection before shipment

After sales service

Our team provides support within one month of product receipt through various communication channels, with solutions typically provided within one week.

For projects requiring durable, high-quality metal components with superior surface finishes, contact us to discuss your specific requirements.